Thepa

-

Fokotsa Mochini oa Mould

Re sebetsa ka thata ho ts'ehetsa Mechini ea Blow Molding, e sebetsanang le liindasteri tse fapaneng.Mechini ea rona e sebelisoa hangata ha ho etsoa lijana tsa botlolo bakeng sa marotholi a mahlo, meriana, litlolo, lijo le litlolo.Leha ho le joalo, ka lebaka la ts'ebetso ea bona e phahameng, theko e tlaase, le boima bo bobebe, masimo a kopo ea bona a ntse a hola ka potlako ho ba likarolo tsa indasteri, haholo-holo likarolo tsa makoloi.Tšebelisano ea rona le kaihua mold e re fa boitseanape le thekenoloji e hlokahalang ho fana ka mechini ea boleng bo holimo ea ho bopa e fihlelang litlhoko tsa hau tse ikhethileng.Re tšepe ho u fa tharollo e tšepahalang litlhoko tsa hau tsa tlhahiso. -

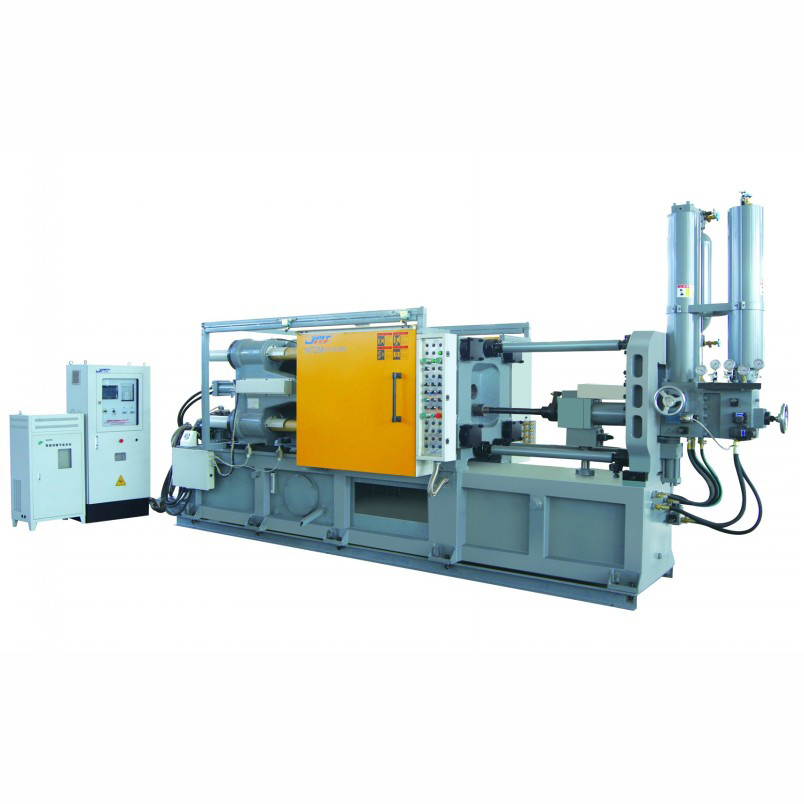

Cold Chamber Die-Casting Machine

Rona ho Kaihua Mold re fana ka Mechini e holimo-limo ea Cold Chamber Die-Casting e etselitsoeng ho hlahisa likarolo tsa boleng bo holimo tsa aluminium le magnesium.Mechini ea rona e na le likarolo tse thata le tse tšoarellang, tse netefatsang ts'ebetso e tšoarellang nako e telele le ts'ebetso e ikhethang.Ka litharollo tsa rona tse bonolo tsa ho sebelisa litsamaiso tse bohlale, u tla ba le monyetla oa ho hlahisa likarolo tse tsamaellanang le lintlha tsa hau hantle.Ho phaella moo, mechine ea rona e hahiloe ka likarolo tse phahameng, tse kang ho laola mocheso o nepahetseng le likarolo tse tsoetseng pele tsa tšireletso.E re re u fe theknoloji e tsoetseng pele eo u e hlokang ho isa khoebo ea hau boemong bo bong.Ikopanye le rona kajeno bakeng sa tlhaiso-leseling e batsi ka Mechini ea rona ea Cold Chamber Die-Casting. -

Mochini o le Mong oa Screw Extrusion

Mochini oa rona oa Single Screw Extrusion Machine ke khetho e phethahetseng bakeng sa bareki ba batlang ho hlahisa lakane ea boleng bo holimo, li-pellets, pipe ea PVC, profiles ea lifensetere, siding ea vinyl, le litlaleho tsa lehong le metsoako ea polasetiki ea fiber ea tlhaho.Kaihua, re utloisisa hore moreki e mong le e mong o na le litlhoko tse ikhethang, ke ka lebaka leo re fanang ka mokhoa o ikhethileng oa ho etsa extrusion.Mechini ea rona e etselitsoe ho eketsa tlhahiso, tlhahiso, le ho nepahala, ha e ntse e fokotsa litšenyehelo.Ka Kaihua, o ka itšetleha ka boitseanape ba rona le lisebelisoa tsa morao-rao ho fana ka liphetho tse hlahelletseng nako le nako.Re tšepe ho u thusa ho isa tlhahiso ea hau boemong bo bong. -

Mochini oa Twin Screw Extrusion

Mochini oa rona oa Twin Screw Extrusion Machine ke tharollo e molemo ka ho fetisisa bakeng sa ho hlahisa lakane ea boleng bo holimo, li-pellets, phala ea PVC, profiles ea lifensetere, siding ea vinyl, le litlaleho tsa lehong le metsoako ea polasetiki ea fiber ea tlhaho.Ka boitseanape ba Kaihua mabapi le moralo le tlhahiso ea hlobo, re fana ka litharollo tse ka khonehang tse eketsang tlhahiso, ho nepahala le tlhahiso, ha re ntse re fokotsa litšenyehelo.Sehlopha sa rona sa litsebi sa lienjiniere se netefatsa hore mechini ea rona e sebelisoa habonolo, ho bonolo ho e hlokomela, 'me e lula e le morao-rao ka tsoelopele ea morao-rao ea theknoloji.Tšepa Kaihua ho u fa Mochini o tšepahalang, o nepahetseng, le oa boleng bo holimo oa Twin Screw Extrusion. -

Mochini oa Motlakase oa Ente ea Motlakase Oohle

Rona ba Kaihua Mold re ikemiselitse ho nts'etsapele Mechini ea Motlakase ea Motlakase e tsoetseng pele haholo.Tsepamiso ea rona ea ho ithuta le ho kenya ts'ebetsong thekenoloji le litsebo tsa maemo a holimo li re nolofalelitse ho fa bareki ba rona litharollo tsa fektheri tse bohlale tsa ente tse ke keng tsa lekanngoa.Thepa e tsoetseng pele ea ts'ebetso le boiphihlelo bo bongata ba tlhahiso eo re fanang ka eona, e ntlafatsa le ho feta bokhoni ba rona ba ho fana ka lihlahisoa tsa boleng bo holimo, tse nepahetseng le tse sebetsang hantle tse hlokomelang litlhoko tse lulang li fetoha tsa 'maraka.Kaihua Mold, re ikitlaelletsa ho ba le boitseanape, maemo a holimo, le ho nepahala nthong e 'ngoe le e 'ngoe eo re e etsang, e leng ho re etsang sebaka sa ho fihla bakeng sa litlhoko tsohle tsa hau tsa ente. -

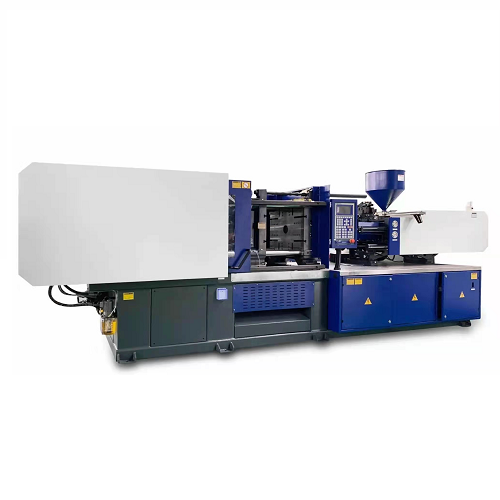

Mochini oa Ho Bopa oa Ente e Otlolohileng

Re fana ka Mechini ea Horizontal Injection Molding ea boleng bo holimo eo ho leng bonolo ho e sebetsa le ho e hlokomela.Mechini ea rona e fana ka phepelo e bonolo 'me e khona ho etsa boikemelo, ho netefatsa tlhahiso e tsitsitseng le e sebetsang hantle.Lisete tse ngata li ka hlophisoa ka mokhoa o ts'oanang ho etsa hore ho be bonolo ho bokella le ho paka lihlahisoa tse entsoeng ka lebanta la conveyor.Ka mechini ea rona ea morao-rao, bareki ba ka thabela linako tsa phetoho e potlakileng le ho nepahala ho ke keng ha bapisoa.Bakeng sa boleng bo ke keng ba lekanngoa le ho ts'epahala, retelehela ho Kaihua Mold bakeng sa litlhoko tsohle tsa hau tsa Horizontal Injection Molding Machine. -

Mochini oa ho Bopa oa Ente e Otlolohileng

Mechini ea rona ea Vertical Injection Molding Machines e fana ka ts'ebetso e nepahetseng e phahameng le ts'ebetso e tsitsitseng.Ho Kaihua Mould, re fana ka lisebelisoa tse felletseng tsa lisebelisoa tse ka kenyelletsang sebopeho sa semela, litharollo tsa IoT, le litharollo tsa boiketsetso le ho boloka basebetsi.Tsepamiso ea rona ea botsebi, boleng bo holimo, le bonolo li netefatsa hore lihlahisoa tsa rona li fihlela litlhoko tsa bareki ba rona.Ka tsebo ea rona ea tlhahiso ea hlobo le mekhoa ea tlhahiso, re kholisehile hore re ka fana ka tharollo e phethahetseng ho finyella litlhoko tsa hau.Khetha Kaihua Mold bakeng sa Mechini ea Mould ea Ente e ka tšeptjoang le e sebetsang hantle. -

Mochini oa ho pshatla polasetiki

Khamphani ea rona, Kaihua Mold, ka boikhohomoso e fana ka Mochini oa Plastiki oa boleng bo holimo o sebelisoang haholo lihlahisoa tse fapaneng tsa polasetiki.Mochine oa rona o lumellana le PE, PP, PVC, PET, Rubber, ABS, PC, le lisebelisoa tse ling tsa litšila.E etselitsoe ho khotsofatsa litlhoko tsa bareki tsa ho nchafatsa, mochini oa rona o silakanyang polasetiki o loketse mefuta eohle ea liphalete, liphaephe, mamati, lifensetere le lipoleiti.Ka thekenoloji ea rona e tsoetseng pele le botsebi ba litsebi, re etsa bonnete ba hore mechini ea rona e maemong a holimo.Ho sa tsotelehe hore na litlhoko tsa hau tsa ho pshatla polasetiki ke life, Mochini oa Polasetiki oa Kaihua Mold ke tharollo e nepahetseng. -

Sekhahla sa polasetiki se boima

Our Heavy-duty Plastic Crusher ke tharollo e phethahetseng bakeng sa lihlahisoa tse fapaneng tsa polasetiki tse kenyelletsang PE, PP, PVC, PET, Rubber, ABS, PC le litšila.E sebelisoa haholo methapong ea tlhahiso hape e ka sebelisoa ka lithapo tsa shredder, ho hlatsoa le ho etsa pelletizing ho fihlela litlhoko tsa bareki.Sehlahisoa sa rona se etselitsoe hore se tšoarelle, se sebetse hantle, 'me se sebetse habonolo.Re sebetsa le Kaihua Mold, moetsi ea ka sehloohong oa hlobo, ho netefatsa boleng bo phahameng ka ho fetisisa.Ka Plastic Crusher ea rona e boima, o ka fetola litšila tsa polasetiki hore e be lisebelisoa tsa bohlokoa ha o ntse o fokotsa tšusumetso ea tikoloho.Khetha sehlahisoa sa rona bakeng sa litharollo tsa profeshenale, tse nepahetseng, le tsa boleng bo holimo. -

Li-Granulator tse se nang skrine

Re ts'ehetsa li-Screenless Granulators ho latela molao-motheo oa ho phunya thipa le thipa e sehang, e ka fihlelang phello ea pulverization e se nang lerole.Li-Granulator tsa Screenless li na le boholo bo nyane, lebelo le tlase, moaparo o tlase, torque e phahameng, e khutsitseng haholo, ea boleng bo holimo le ts'ebetso e ntle haholo. -

Li-Granulator tse nang le molumo

Kaihua Mold e motlotlo ho fana ka li-Granulator tsa rona tsa Sound-proof, tse etselitsoeng ka ho khetheha bakeng sa ho sebelisoa bocha ha litšila le likarolo tse lahliloeng ho tloha ho enteng, ho bōptjoa ha molumo kapa lithapo tsa extrusion.Mechini ea rona e na le sebopeho se ntlafalitsoeng se netefatsang ts'ebetso e bonolo le ho khutlisa blade ka potlako, ho etsa hore ho be bonolo ho e sebelisa.Li-granulator tsena tse nang le bopaki ba molumo ke khetho e ntle bakeng sa lik'hamphani tse batlang ho fokotsa likhase tsa bona tsa khabone ha li ntse li ntlafatsa ntlha ea tsona ea mantlha.'Me ka boitlamo ba Kaihua Mold ba ho fana ka litharollo tsa boleng bo holimo tse fihlelang maemo a boima a indasteri, u ka kholiseha hore u tsetela khoebo ea hau hantle.Ikopanye le rona kajeno ho ithuta haholoanyane ka li-Granulator tsa rona tse thibelang molumo. -

Mochine o chesang oa Chamber Die-Casting

Re fana ka mefuta e mengata ea Mechini ea Hot Chamber Die-Casting, e etselitsoeng ho fihlela litlhoko tse fapaneng tsa indasteri.Mechini ea Hot Chamber Die-Casting hangata e sebelisoa ho akhela li-alloys tse tlase-tlase, joalo ka alloy ea zinc.Mechini ea rona e hahiloe ka thata ebile e na le litharollo tsa sistimi e bohlale ho u fa maemo a bonolo le ts'ebetso e phahameng.Re boetse re fana ka Kaihua Mold, e leng sebopeho sa boleng ba boleng ba boleng ba pele bakeng sa ho lahla, ho netefatsa tlhahiso ea nako e telele le e nepahetseng ea sehlahisoa.Ka Mechini ea rona ea Hot Chamber Die-Casting le Kaihua Mold, o ka hlahisa likarolo tsa boleng bo holimo le tse nepahetseng bakeng sa litlhoko tsa indasteri ea hau.