Basehang

- 1.Selelekela sa Sehlahisoa

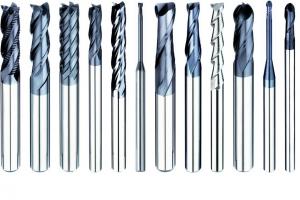

Li-cutters tse tsoang Kaihua Mold ke tharollo e phethahetseng bakeng sa mesebetsi ea machining e hlokang ho nepahala le ho nepahala.Re fana ka mefuta e mengata e fapaneng ea li-milling cutters ho kenyelletsa li-cutter tsa cylindrical milling, li-face cutters, li-milling, le tse ling.Li-milling cutters tsa rona li khona ho etsa li-grooves tse bataletseng, ho etsa bokaholimo, le ho seha lisebelisoa tsa mosebetsi habonolo.Hore na o sebetsa ka thepa e thata joalo ka tšepe kapa lisebelisoa tse bonolo joalo ka polasetiki, li-milling cutters li etselitsoe ho fana ka liphetho tsa boleng bo holimo nako le nako.Li-cutters tsa rona tsa cylindrical milling li entsoe ka tšepe e phahameng ka lebelo kapa thepa ea carbide, e fanang ka nako e telele le bophelo bo bolelele ba ts'ebeletso.Li loketse likopo tse hlokang ho nepahala ho phahameng le mamello e thata.

Li-cutter tsa rona tsa sefahleho li loketse ho sebetsa ka thata le ho qeta, 'me li ka hlahisa libaka tse bataletseng habonolo.Li entsoe ka mekhoa e tsoetseng pele ea tlhahiso, e netefatsang boemo bo phahameng ba ho nepahala le ho sebetsa.Bakeng sa mesebetsi e rarahaneng ea machining, li-mill tsa rona ke tharollo e phethahetseng.Li etselitsoe ho khaola mahlakoreng 'ohle' me li ka sebelisoa ho theha mefuta e mengata ea libopeho le li-contours.

Ho Kaihua Mold, re utloisisa hore mosebetsi o mong le o mong oa mochini o ikhethile, ke ka lebaka leo re fanang ka li-cutter tse tloaelehileng.Sehlopha sa rona sa litsebi se ka sebetsa le uena ho rala le ho etsa li-milling cutters tse fihlelang litlhoko tsa hau tse ikhethileng.Re sebelisa thekenoloji ea morao-rao le lisebelisoa tse tsoetseng pele ho hlahisa lisebelisoa tsa boleng bo phahameng, tse sebetsang hantle haholo tse khonang ho mamella le maemo a thata ka ho fetisisa a ho sebetsa.

Qetellong, haeba u batla li-cutters tsa boleng bo holimo tse ka fanang ka liphetho tse nepahetseng, tse nepahetseng nako le nako, u se ke ua sheba hole le Kaihua Mold.Lihlahisoa tsa rona li etselitsoe ho khotsofatsa litlhoko tsa mefuta e mengata ea liindasteri, ho kenyelletsa le likoloi, sefofane, bongaka, le tse ling.Ikopanye le rona kajeno ho ithuta haholoanyane ka lihlahisoa le litšebeletso tsa rona.

- 2.Molemo

Ho tsitsa - Butle-butle khaola ka lintho tse bonahalang, ho itšeha matla ke e nyenyane tla ka seoelo hlaha robehileng sesebelisoa

Ho nepahala ho phahameng

Ho potoloha ka lebelo le phahameng la sesebelisoa le ho kenella ha shaft e kholo ho loketse ho qeta ho etsa mochini oa ho tlosa chip ea kahare.

Bokgoni bo phahameng

Moralo oa li-groove tse ngata o eketsa palo ea li-cutlets e le hore lebelo la phepelo le ka eketsoa habonolo

Qetello e ntle

Litsenyehelo tsa tlhōlisano