Ho fihla ho 1100L-660L Waste Bin Ente Mold

1.Selelekela sa Sehlahisoa

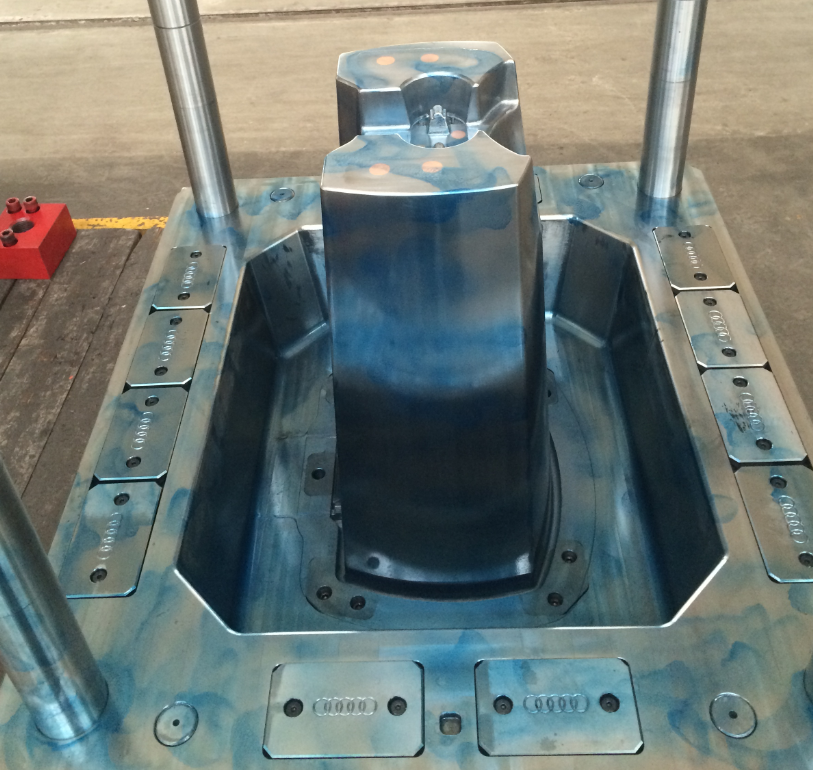

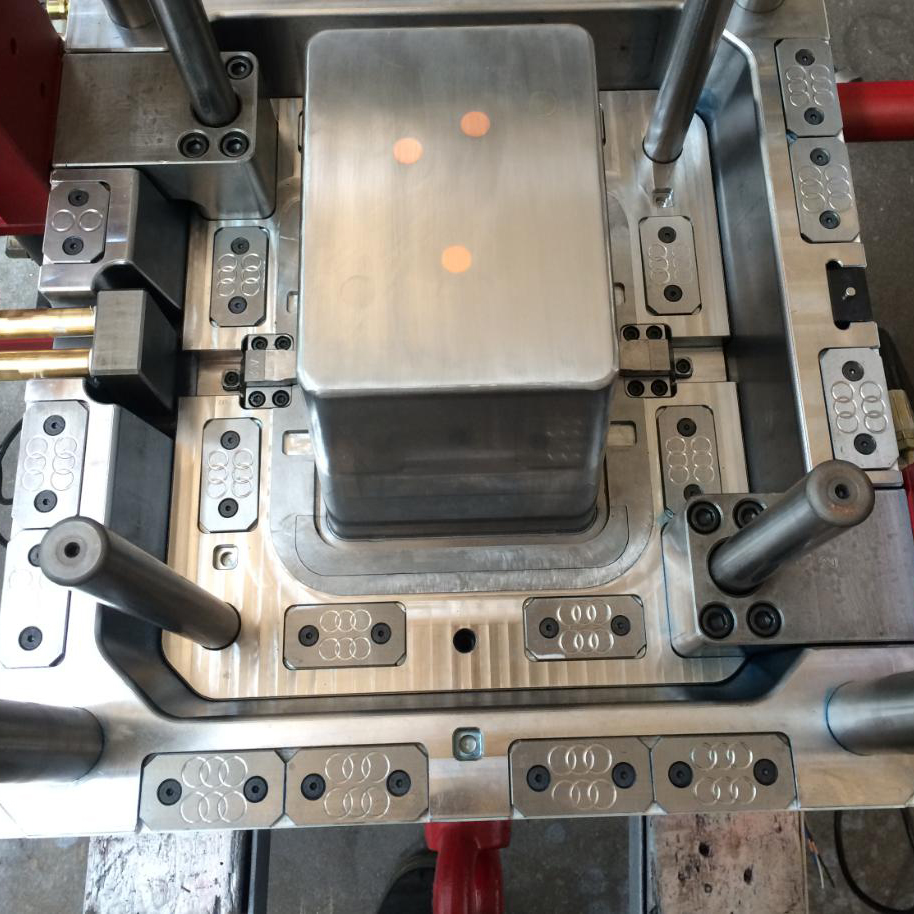

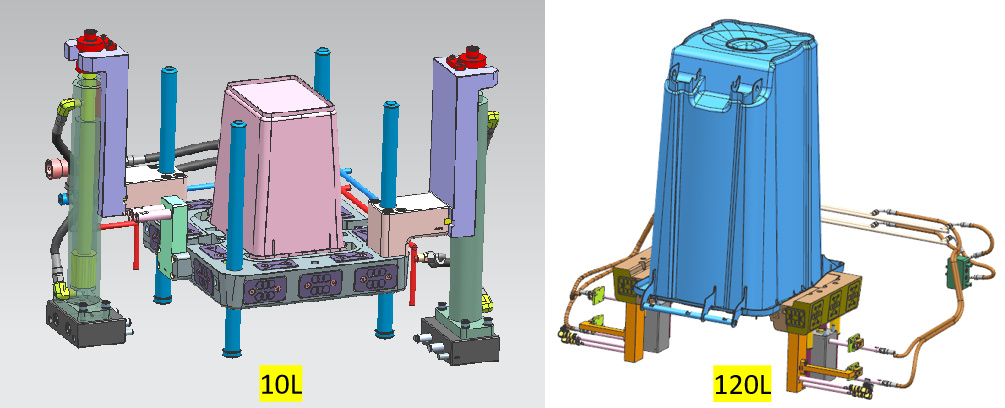

Joaloka moetsi ea ka sehloohong oa hlobo ea ente, Kaihua Mold e motlotlo ho fana ka litharollo tsa hlobo tsa ente ea litšila tsa boleng bo holimo.Mefuta ea rona e kenyelletsa hlobo bakeng sa li-bins ho tloha ho 10L ho ea ho 42L, ho fihlela ho 1100L, ho etsa bonnete ba hore re ka finyella litlhoko tsa mofani ofe kapa ofe, ho sa tsotellehe boholo ba morero oa bona.

Sehlopha sa rona sa litsebi se qetile lilemo se ntse se etsa lipatlisiso le ho hlahisa litharollo tsa ho bōpa tse sebetsang hantle ka ho fetisisa le tse theko e tlaase, ho thusa bareki ba rona ho boloka litšenyehelo tsa tlhahiso le ho bopa.Re utloisisa bohlokoa ba ho khona ho fetola liphetolelo kapele, ke ka lebaka leo re entseng liforomo tsa rona ho etsa hore ts'ebetso ena e be bonolo kamoo ho ka khonehang.

Hore na o batla hlobo bakeng sa moqomo oa lithōle, moqomo oa lithōle, moqomo oa lithōle, kapa moqomo oa lithōle seterateng, re na le tharollo bakeng sa hau.Mefuta eohle ea rona e hahiloe bakeng sa ts'ebetso e nepahetseng, ka linako tse potlakileng tsa potoloho le bophelo bo bolelele ba hlobo, ho netefatsa hore tlhahiso ea hau e tsamaea hantle le ka katleho.

Litharollo tsa rona tsa ente ea litšila li nepahetse bakeng sa likhoebo le mekhatlo e batlang ho ntlafatsa lits'ebetso tsa bona tsa taolo ea litšila.Mefuta ea rona ke ea boleng bo holimo, e fana ka ts'ebetso e tšoarellang le e tšepahalang e tla tšoarella lilemo tse tlang.

Kaihua Mold, re ikemiselitse ho fihlela litlhoko tsa bareki ba rona ka ho fana ka lihlahisoa tsa boleng bo holimo tse nang le moralo le ts'ebetso e ke keng ea lekanngoa.Ikopanye le rona kajeno ho ithuta haholoanyane ka tharollo ea hlobo ea ente ea litšila le kamoo re ka u thusang ho ntlafatsa mekhoa ea hau ea tlhahiso.

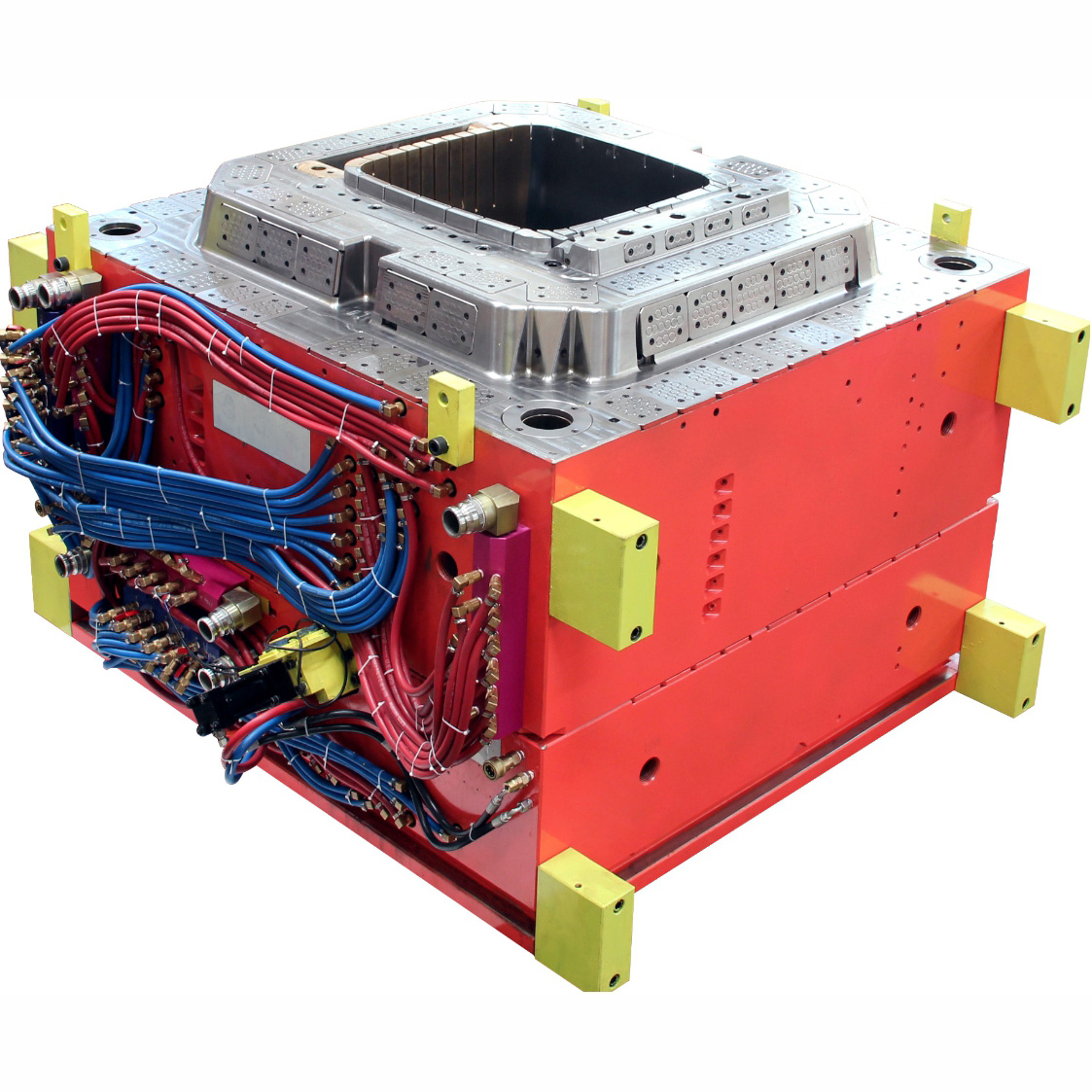

2.Sehlahisoa parameter (Tlhaloso)

| Brand | Kaihua |

| Mold Base | LKM, HASCO, DME kapa tlhoko ea hau |

| Mold | 45 #, P20, H13, 718, 1.2344, 1.2738 kapa tlhoko ea hau |

| Standard | HASCO, DME, MISUMI, PUNCH, kapa tlhoko ea hau |

| Boitsebiso ba Sehlahisoa | PC/ABS, ABS, PC, PVC, PA66, POM kapa tlhoko ea hau |

| Semathi | Semathi se batang/se chesang |

| Mofuta oa HekeLihlahisoa tsa boholo | Side gate, Sub gate, Pin point gate, Edge gate etc10L-42L, ho fihlela ho 1100L.kapa tlhoko ea hau |

3.Sehlahisoa Sebopeho le Tšebeliso

4.Lintlha tsa Tlhahiso

Re khona ho lekola moralo oa hlobo oa ente le ho etsa lipapiso tsa litsebi ho etsa bonnete ba hore moralo oa sehlahisoa o ka lumellana le maemo a fapaneng.

Mohlala, litloaelo tsa EN 840 bakeng sa lijana tsa litšila tse tsamaeang.

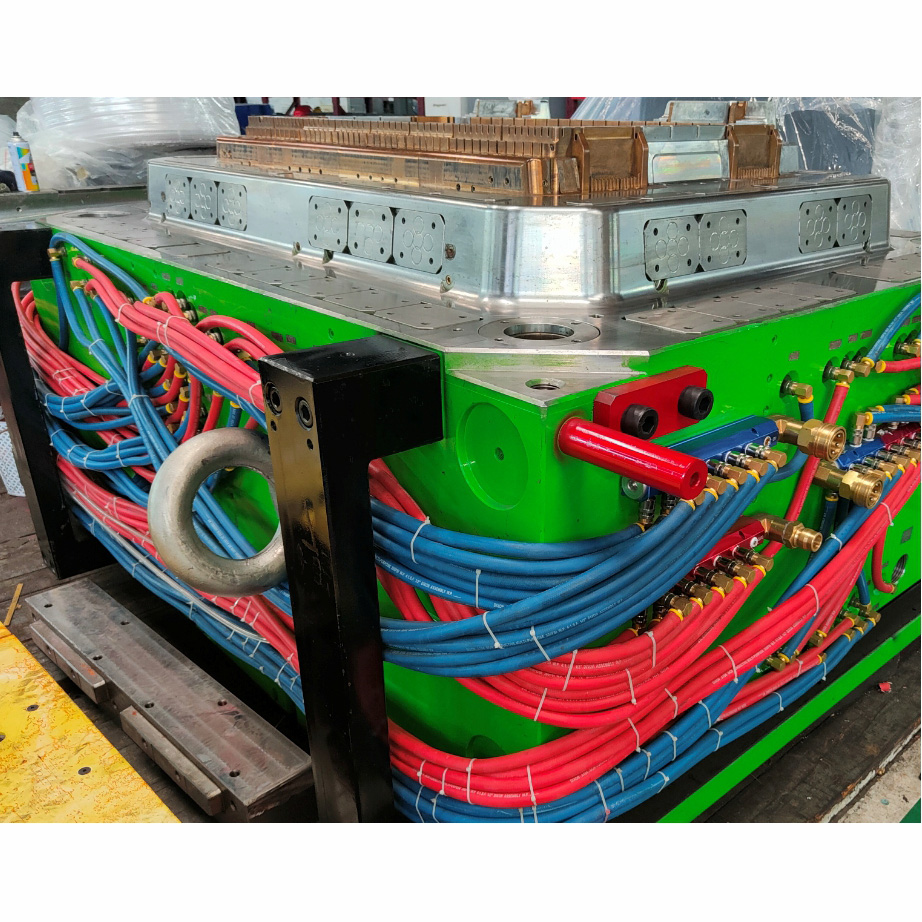

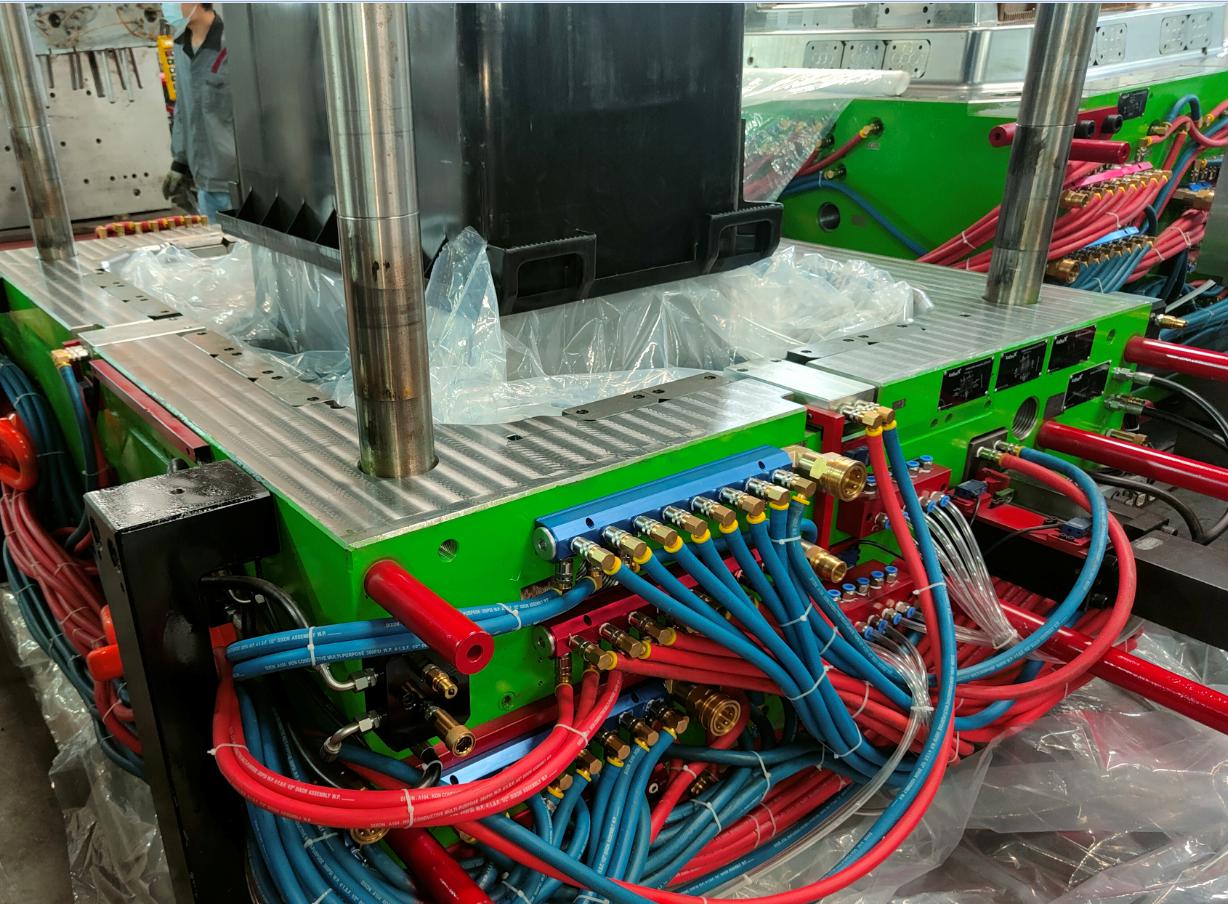

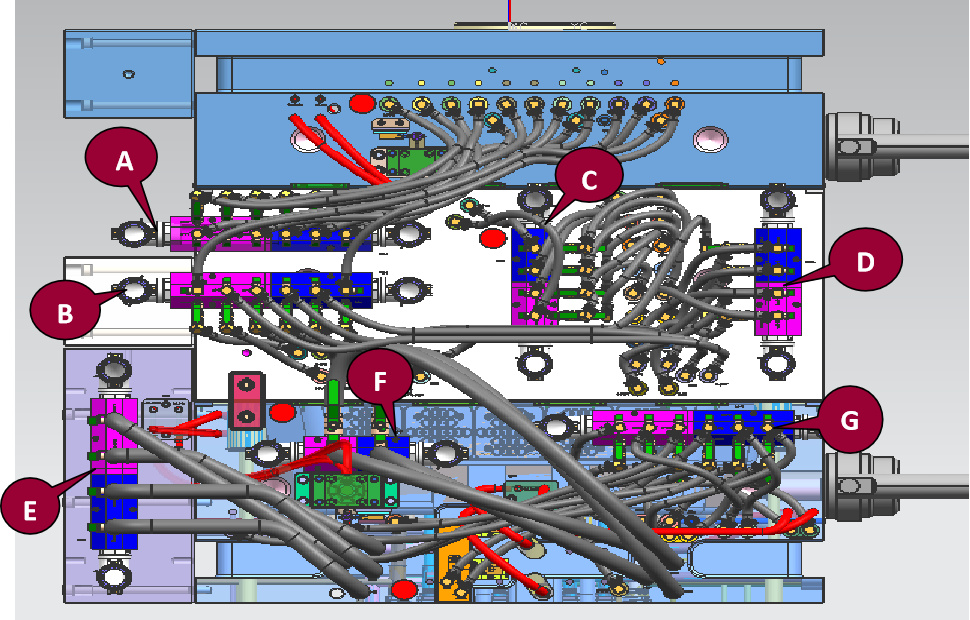

5.Ho pholisa

Mohlala: Moqomo oa litšila oa 240L

Nako ea baesekele: ≦ 60s ho kenyelletsa ho lata roboto

Ho na le li-7pcs tse ikemetseng tse pholileng tse nang le lihokelo tse kholo tsa inlet / outlet, tseo re ka li sebelisang ho laola mocheso oa libaka ka 'ngoe.

lehlakore la cavity: A, B, C le lehlakore la Dcore: E, F le G

Mehaho e mengata ea ho pholile ka

valve e tla netefatsa taolo ea phallo ea metsi.

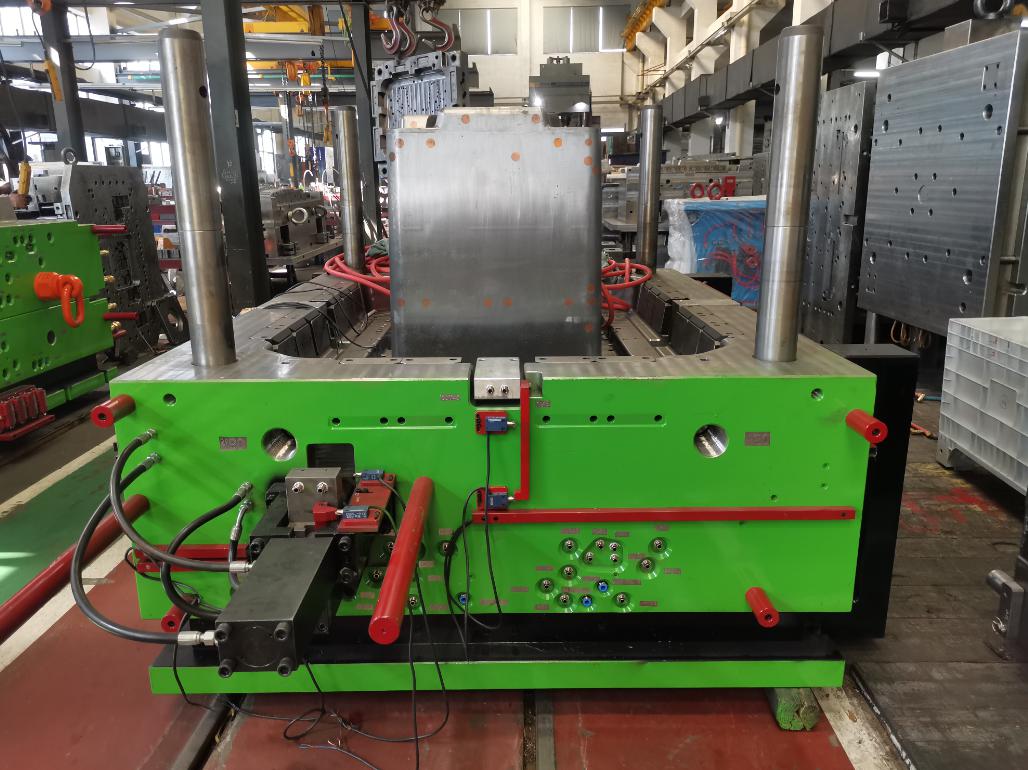

6.Ho ntšoa

Re tla rala sistimi e ntle le e tšepahalang ea ejection.

Ka linako tse ling e tla ba li-ejector blocks, kapa e ka ba poleiti ea stripper le eona.

Ka linako tse ling re sebelisa li-valve tsa moea le roboto feela ho ntša likarolo.

Ejection e tlameha ho ba bonolo ka hohle kamoo ho ka khonehang le moralo bakeng sa tlhokomelo e bonolo.

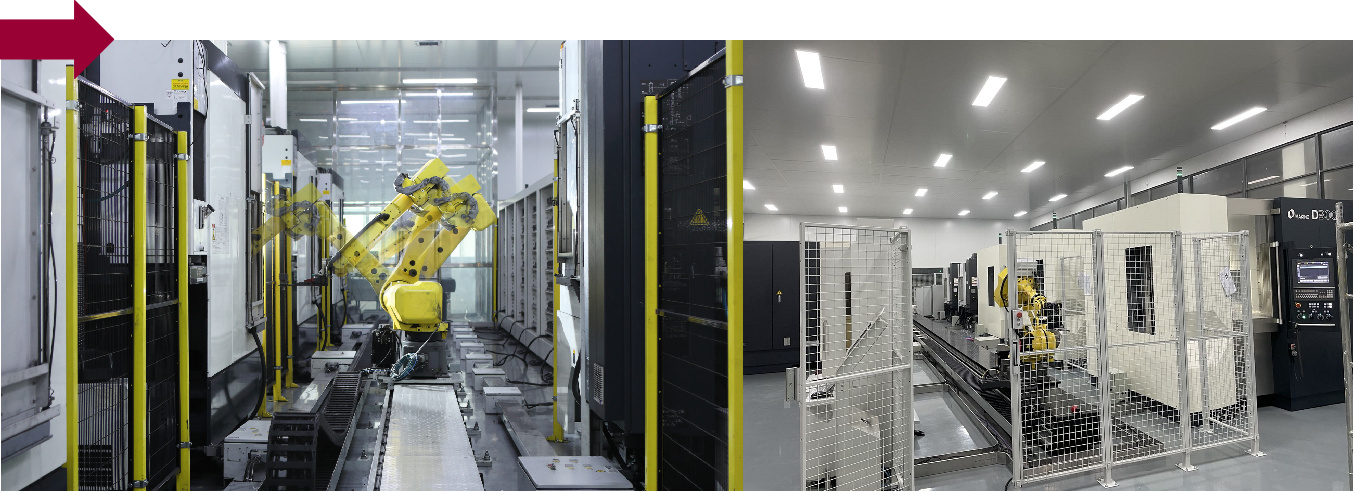

7.Mechine

CNC e nyane ho isa ho e kholo ho kenyelletsa le 5 axis high speed CNC

MAKINO Automation line

Mochine oa ho shebella 100-500T,

e kgonang ho etsa mefuta yohle ya moento

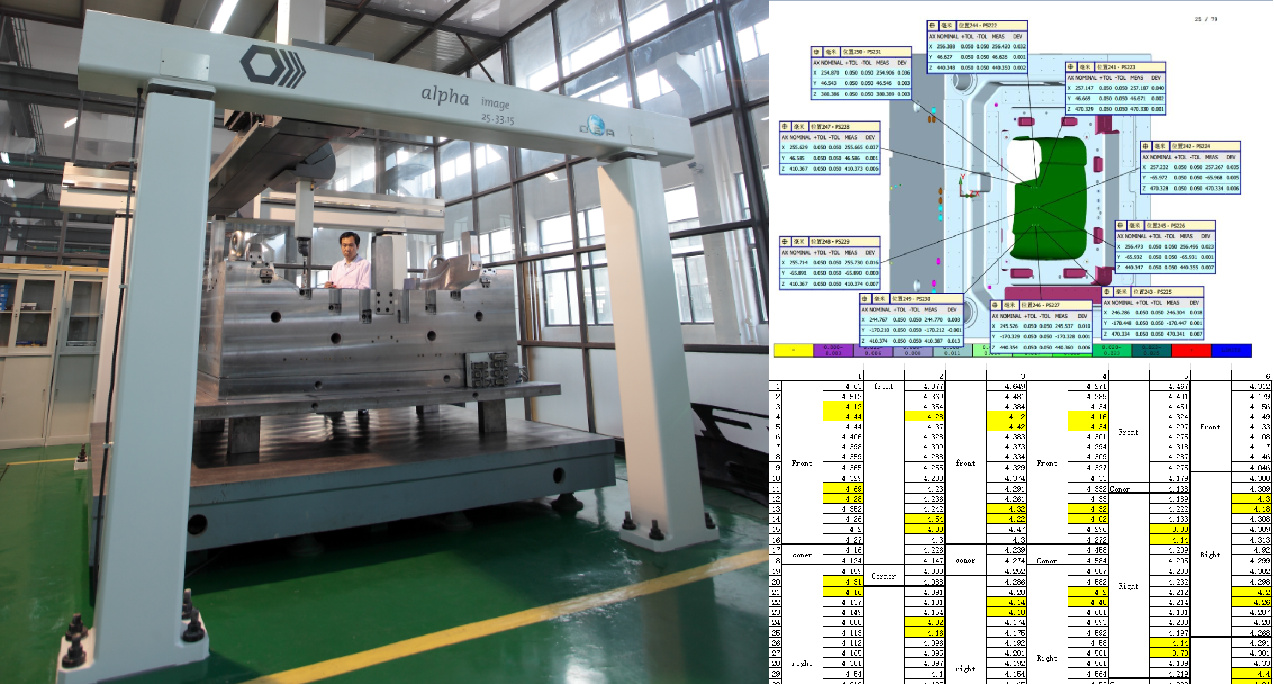

CMM – boholo/botenya

Mechini ea Krauss Maffei, kaofela e nang le liroboto,

ho tloha ho 160-1600T (ente e ngata)

Mochini oa ente ea 3200T, metsamao e ts'oanang, hydraulic clamping, e nang le roboto ea 6-axix ABB.

Ha se mochine o moholo ka ho fetisisa oo re nang le oona.Ha joale re reka mochini oa ente ea 5500T.

8.Melemo

√ Eketsa katleho le ho fokotsa tšebeliso ea matla.

√ Moralo o koetsoeng ka botlalo le ho tiisa molumo o netefatsa boemo bo tlase ba lerata..

√ Thepa ea lehare ke tšepe e tsoang kantle ho naha ho netefatsa boleng bo holimo le bo tšoarellang bo phahameng.

√ E na le relay ea motlakase ea hona joale, sesireletsi sa motor overload le lisebelisoa tse ling tse ngata tsa polokeho.√ Phetoho e bonolo ea enjene.

√ Se arola lerole, sesebelisoa sa alamo se amohelang ka botlalo le li-skrini tse khethehileng.

● Boleng bo Phahameng (Sehlahisoa &Mould)

● Thomello ka Nako (Mohlala, Mould)

● Taolo ea Litšenyehelo (Litšenyehelo tse tobileng, Litšenyehelo tse sa Tobang)

● Tšebeletso e Molemo ka ho Fetisisa (Bareki, Basebetsi, Lefapha le Leng, Mofani)

● Foromo— ISO9001:2008 Litsamaiso tsa tsamaiso ea boleng

● Ts'ebetso-Tsamaiso ea Morero

● Tsamaiso ea tsamaiso ea ERP

● Maemo a Maemo—Taolo ea Tshebetso